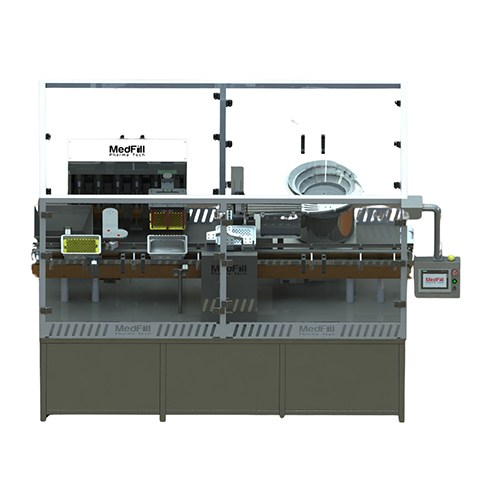

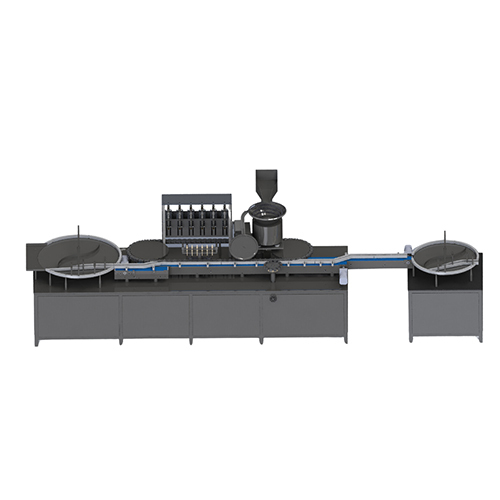

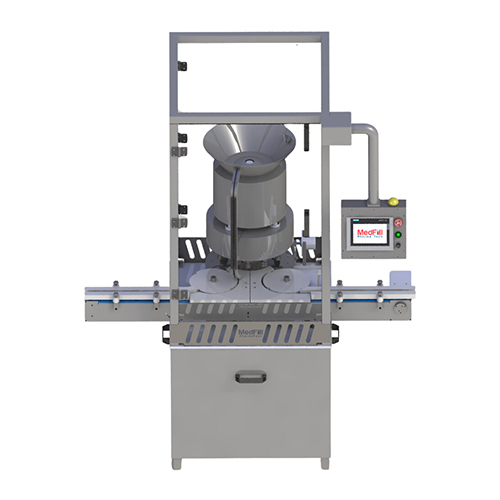

Most Popular Products

Precision Delivered with Fully Automatic PFS Machines, Injectable Powder Filling Machines, Cap Sealing, and Liquid Inspection Systems.

Medfill Pharmatech is committed to redefining injectable pharmaceutical machinery standards through precision engineering, smart automation, and unrivaled functionality. As a supplier and producer, the firm provides a range of specialized machines that meet the demanding needs of injectable manufacturing. Fully automatic type pfs machine, weight-based rejection injectable liquid filling machine, aluminium cap sealer machine, injectable dry powder filling machine, and industrial visual inspection machine are carefully crafted to be compliant with GMP, to ensure sterility assurance, and for efficient operation. Through the incorporation of advanced technologies like real-time quality inspection, weight checking, and smart rejection systems, the equipment not only reduces product loss but also provides consistent accuracy in high-speed production environments. From compact footprint designs to easy-to-use HMI interfaces, every aspect reflects user-centric innovation. Machines are made easy to insert into existing lines, with provision for varying container formats and rapid format changeover capabilities that make operations across various production batches more convenient. With remote technical support, preventive maintenance, and certified cleaning processes, the life of each machine is optimized and downtimes are significantly reduced.

Backed by advanced contamination prevention mechanisms and programable recipe management systems, all equipment is the pinnacle of engineering perfection and industry regulation. We offer the highest level of data integrity, audit-ready reports, and multi-language operator training to enable manufacturers to confidently meet global requirements.

Mission & Vision

The purpose is to provide high-performance injectable filling and inspection machines that enable pharmaceutical manufacturers to enhance sterility, precision, and conformance in manufacturing. The company's vision is to be a trusted global partner for smart, efficient, and innovative injectable processing equipment, driving technology advancement and establishing standards in quality and customer-centric design.

Backed by advanced contamination prevention mechanisms and programable recipe management systems, all equipment is the pinnacle of engineering perfection and industry regulation. We offer the highest level of data integrity, audit-ready reports, and multi-language operator training to enable manufacturers to confidently meet global requirements.

Mission & Vision

The purpose is to provide high-performance injectable filling and inspection machines that enable pharmaceutical manufacturers to enhance sterility, precision, and conformance in manufacturing. The company's vision is to be a trusted global partner for smart, efficient, and innovative injectable processing equipment, driving technology advancement and establishing standards in quality and customer-centric design.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese